Triumph Ignition Timing - Page 2

Triumph Ignition Timing - Page 2

|

Macy's Garage, Ltd. America's BEST Triumph Shop! |

Welcome to page two of our discussion of ignition timing, specifically as it applies to Triumph TR2, TR3, and TR4 sports cars. We’ve already covered the what’s and why’s of ignition timing, so now we can roll up our sleeves and get to the “how’s”.

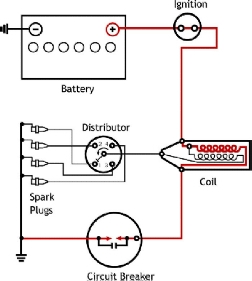

The first how we need to know about to set the initial timing is how we know the exact moment that a spark plug is going to fire. For that answer, I need to explain how the ignition system in our Triumphs works.

It all starts with the

12-volt battery, and electricity’s desire to flow from the positive battery

terminal to the negative battery terminal. Even though batteries were

originally installed in our Triumphs with the positive terminal connected to

ground, I’m going to explain this as if your car has been converted to negative

ground, because it seems to make more sense (at least to me). In basic terms,

electrical current flows from the positive battery terminal to the negative

terminal. The engine’s ignition system is one of many paths that the electricity

can take. The current flows from the positive battery terminal through a wire

to the ignition switch, and if the switch is “ON” continues to the “+” terminal

of the coil. Of course if the switch is “OFF”, then the current flow stops and

the ignition system is disabled.

It all starts with the

12-volt battery, and electricity’s desire to flow from the positive battery

terminal to the negative battery terminal. Even though batteries were

originally installed in our Triumphs with the positive terminal connected to

ground, I’m going to explain this as if your car has been converted to negative

ground, because it seems to make more sense (at least to me). In basic terms,

electrical current flows from the positive battery terminal to the negative

terminal. The engine’s ignition system is one of many paths that the electricity

can take. The current flows from the positive battery terminal through a wire

to the ignition switch, and if the switch is “ON” continues to the “+” terminal

of the coil. Of course if the switch is “OFF”, then the current flow stops and

the ignition system is disabled.

Now the coil is an interesting part, because it has the ability to turn the 12-volt electricity from the battery into the 20-30,000 volts (or more) needed to cause a spark to jump across the spark plug terminals. How does it do that? There are actually two coils (windings) of wire inside a “coil”, a primary coil around the outside and a separate inner or secondary coil. When electricity from the battery flows through the primary windings it produces a magnetic field, which affects the inner (secondary) windings. If the current flow (from the battery) through the primary coil windings is suddenly stopped, the magnetic field collapses, which induces a current in the secondary coil windings. The much larger number of coil windings in the secondary coil cause it to produce the high voltage necessary to jump the spark plug gap, and ignite the fuel/air mixture in your engine.

How is it that we are able to stop this flow of electricity through the primary coil windings each time that we want a spark plug to fire? That’s the job of the breaker points (usually referred to as simply “points”) in the distributor. In our example of a negative ground battery system, a small wire from the “-“ side of the coil goes to the distributor and continues inside where it connects to the points. (If your car is positive ground, then the connections to the “+” and “-“ terminals of the coil should be reversed.)

The

points in our 4 cylinder Triumph engines are mounted inside the distributor (under the

distributor cap), and they have a small rubbing block that touches a square lobe

on the distributor’s shaft. As the distributor shaft turns, the square lobe

also turns. When each of the four corners on the lobe move past the rubbing

block, the electrical contact points are forced apart (open) and the flow of

electricity stops. When a corner of the lobe is not pushing the points open,

they touch and the electricity flows through to the engine/chassis/body (ground)

and back to the negative battery terminal. By determining the exact moment that

the points open and stop the current flow, we are able to know precisely when

the coil will produce the powerful spark, and the spark plug will fire. This

knowledge will allow us to precisely set the timing.

The

points in our 4 cylinder Triumph engines are mounted inside the distributor (under the

distributor cap), and they have a small rubbing block that touches a square lobe

on the distributor’s shaft. As the distributor shaft turns, the square lobe

also turns. When each of the four corners on the lobe move past the rubbing

block, the electrical contact points are forced apart (open) and the flow of

electricity stops. When a corner of the lobe is not pushing the points open,

they touch and the electricity flows through to the engine/chassis/body (ground)

and back to the negative battery terminal. By determining the exact moment that

the points open and stop the current flow, we are able to know precisely when

the coil will produce the powerful spark, and the spark plug will fire. This

knowledge will allow us to precisely set the timing.

But before we can actually set the timing, we must be certain that the points are adjusted correctly. The points primarily stop the flow of electricity through the coil’s primary windings, but they are also important for allowing the current flow through the coil as well. Current must be able to flow through the primary coil windings long enough to set up the magnetic field, or the high voltage the plugs need won’t be created. To assure that the points are both open and closed for adequate amounts of time, the points must be adjusted properly. This is an important first step in setting your engine’s timing.

To adjust your points, you will need a screwdriver (or two), and a .015” thick feeler gauge. Remove the distributor cap and rotor to gain access to the points, then rotate the engine until the rubbing block is resting on the highest point of any corner on the square lobe. To assure proper operation, we want to adjust the gap between the two contact points to be exactly .015” when they are separated the greatest amount, so it’s important to have the rubbing block placed on a high point of the lobe.

Begin by inspecting the mating surfaces of the two contact points. They should be flat and smooth for best results, and if they appear burned or pitted, replace with a new points set. Points adjustment starts by making certain that the ignition switch is “OFF”, then gently slide the feeler gauge between the two contact points to measure the gap between them. Watch to see that the feeler gauge does not force the points apart, which would indicate too narrow of a gap (less than .015”). Too wide of a gap is easy to see, and the feeler gauge will be loose and able to be move from side to side. If either of these conditions indicates that the gap is something other than .015”, they will need to be adjusted.

To

adjust the point gap, you’ll have to loosen the mounting screw slightly, then

move the points closer to or farther away from the cam lobe to lessen or

increase the gap. There’s a slot at one end of the points where a screwdriver

can be placed and twisted with one hand to move the points in and out, while you

drag the feeler gauge through the gap with your other hand and feel for a slight

drag. (This is easier if you leave the mounting screw just tight enough that

the points will stay where you put them!) Tighten the mounting screw and

re-check the gap with your feeler gauge. I often think that Lucas designed

these distributors to be best serviced by three handed mechanics, because it’s

not unusual for the points adjustment to change when you tighten the screw. If

the points did move and your feeler gauge doesn’t have the same slight drag as

you slide it through the gap, loosen the screw and start all over again.

Re-install the rotor when the points adjustment has been completed.

To

adjust the point gap, you’ll have to loosen the mounting screw slightly, then

move the points closer to or farther away from the cam lobe to lessen or

increase the gap. There’s a slot at one end of the points where a screwdriver

can be placed and twisted with one hand to move the points in and out, while you

drag the feeler gauge through the gap with your other hand and feel for a slight

drag. (This is easier if you leave the mounting screw just tight enough that

the points will stay where you put them!) Tighten the mounting screw and

re-check the gap with your feeler gauge. I often think that Lucas designed

these distributors to be best serviced by three handed mechanics, because it’s

not unusual for the points adjustment to change when you tighten the screw. If

the points did move and your feeler gauge doesn’t have the same slight drag as

you slide it through the gap, loosen the screw and start all over again.

Re-install the rotor when the points adjustment has been completed.

Once the points are correctly adjusted, you’re ready to set the initial timing. There are two ways to manually change the initial timing on your distributor. One is by turning the external thumbscrew, and the other is by loosening the distributor clamp and rotating the distributor body itself. We’ll use a combination of both to get the correct setting.

Because we’ll be using the external thumbscrew later in the process, it’s helpful to make sure it is resting in the middle of the adjustment range. Begin by turning the thumbscrew as far as it will go in either direction, then count the number of turns as you move it to the opposite stop. Divide that number in half, and return the screw to the middle of its range. Now you’ll have adequate adjustment in either direction should you need it later.

We’ve

finally reached the point where we can set the initial timing, and the next

thing we must do is determine when the #1 piston is at Top Dead Center (TDC).

With the gearbox in neutral, you should be able to turn the engine (clockwise

when viewed from the front of the car) by hand until the timing mark on the

crankshaft pulley lines up with the pointer on the engine’s timing cover. As

long as someone has not assembled the hub and pulley incorrectly (see the

factory workshop manual for more on this), the #1 and #4 pistons should both be

at TDC. You can set the distributor cap loosely in place and if the rotor

points to the #1 or #4 terminal locations, you can proceed with the timing

adjustment. If you go past the place where the two marks line up, don’t just

back it up a small amount to align them. Back it up well past the correct

location, and approach the spot again with a clockwise rotation of the

crankshaft (to take up any possible “slop” due to a worn timing chain or gears

inside the engine) or rotate the crankshaft another full revolution in the

clockwise direction and try it again.

We’ve

finally reached the point where we can set the initial timing, and the next

thing we must do is determine when the #1 piston is at Top Dead Center (TDC).

With the gearbox in neutral, you should be able to turn the engine (clockwise

when viewed from the front of the car) by hand until the timing mark on the

crankshaft pulley lines up with the pointer on the engine’s timing cover. As

long as someone has not assembled the hub and pulley incorrectly (see the

factory workshop manual for more on this), the #1 and #4 pistons should both be

at TDC. You can set the distributor cap loosely in place and if the rotor

points to the #1 or #4 terminal locations, you can proceed with the timing

adjustment. If you go past the place where the two marks line up, don’t just

back it up a small amount to align them. Back it up well past the correct

location, and approach the spot again with a clockwise rotation of the

crankshaft (to take up any possible “slop” due to a worn timing chain or gears

inside the engine) or rotate the crankshaft another full revolution in the

clockwise direction and try it again.

Now

all that’s needed is to position the distributor so that the points have opened

just enough to stop the flow of electricity through the coil with the piston at

TDC. To determine where this place is, you’ll need a 12-volt test light (which

can be purchased inexpensively from any automotive parts or tool store or home

made). Because electricity is somewhat ‘lazy’, it will always take the easiest

path as it tries to return to the battery. The current will flow through the

points when they are closed as opposed to flowing through a test light where it

would have to do some ‘work’ on the way back to the battery. When the points

open however, the only option left for the electricity to get back to the

battery is through the light and it immediately takes this new return path,

lighting the test bulb along the way! Therefore, with the ignition switch “ON”,

if you touch one side of your test light to the distributor side of the coil,

and attach the other side to a ground, the light will come on at the very

instant that the points “open” and the spark plug would fire. Simply loosen the

clamp at the base of the distributor, and rotate the distributor until you find

the spot where the light just blinks on with any movement of the distributor.

Remember that the square lobe rotates counter-clockwise, so you’re looking for

the spot where the points will just open, not the closing point on the “back

side” of the lobe’s rotation. Turn off the

ignition switch, and tighten the distributor clamp. Add a tiny amount of

lubrication to the rubbing block to reduce wear, and you’re almost done.

Now

all that’s needed is to position the distributor so that the points have opened

just enough to stop the flow of electricity through the coil with the piston at

TDC. To determine where this place is, you’ll need a 12-volt test light (which

can be purchased inexpensively from any automotive parts or tool store or home

made). Because electricity is somewhat ‘lazy’, it will always take the easiest

path as it tries to return to the battery. The current will flow through the

points when they are closed as opposed to flowing through a test light where it

would have to do some ‘work’ on the way back to the battery. When the points

open however, the only option left for the electricity to get back to the

battery is through the light and it immediately takes this new return path,

lighting the test bulb along the way! Therefore, with the ignition switch “ON”,

if you touch one side of your test light to the distributor side of the coil,

and attach the other side to a ground, the light will come on at the very

instant that the points “open” and the spark plug would fire. Simply loosen the

clamp at the base of the distributor, and rotate the distributor until you find

the spot where the light just blinks on with any movement of the distributor.

Remember that the square lobe rotates counter-clockwise, so you’re looking for

the spot where the points will just open, not the closing point on the “back

side” of the lobe’s rotation. Turn off the

ignition switch, and tighten the distributor clamp. Add a tiny amount of

lubrication to the rubbing block to reduce wear, and you’re almost done.

You’ve just set the ignition timing to fire the spark plugs when each piston has reached TDC, but Triumph has specified that this setting should actually be 4 degrees before TDC. How are we going to do this? This is the easy part. Just turn the external thumbscrew in the “A” direction (advance) as indicated by the arrow. There is a reference line through the middle the thumbscrew, and one complete turn is equal to 8 degrees of adjustment. Therefore, note the position of the reference line and turn the screw ½ turn in the “A” direction to set your ignition timing at the factory recommended 4 degrees BTDC.

Congratulations! Your timing is now set. Re-install the distributor cap, pick up all of your tools, and take that Triumph TR out for a drive!

BACK to Timing Page 1