Macy’s Garage

© 2026 - Macy’s Garage, Ltd.

Blog

WHAT we’re doing, and HOW we’re doing it!

June 29, 2020

Preparing to paint the signature stripe on a TR250 is a lengthy and tedious process. Moss has a nice instruction sheet available, but because none of the lines are parallel to a straight body line, and crossing surfaces that are anything but flat, it takes great care and patience to get the stripe layed out correctly. We don’t want to chance that the stripe won’t align from panel to panel, so we always assemble the fenders and hood, and then begin the taping process. Don’t forget to install the fender beading as well, because the stripe goes right across the painted beads. We can assume that Triumph did not take this kind of time when laying out these stripes, and it would have been interesting to see what kind of stencil or mask they used to fit one to such a convoluted surface. We know the stripe was applied with the front ends completely assembled because we’ve seen original cars with overspray in the cracks between fenders and hood, but we always take them back apart to paint after the layout is complete. That way we can tape off the back sides and control the overspray, making a much neater job than could have been accomplished in a production factory.June 22, 2020

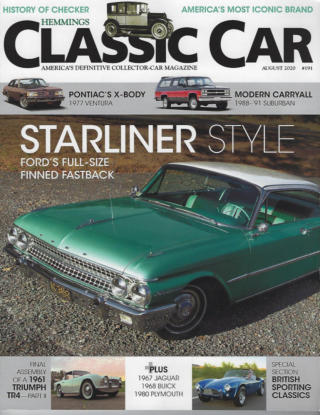

The August 2020 issue of “Hemmings Classic Car” is here, and once again there’s a Triumph TR4 on the cover! Part two of the 2-issue feature on Tonda’s earlyTR4, CT288L is included on pages 80-85, and covers the final assembly and some of the details which distinguish this and other early production TR4’s from the later cars that followed. Executive Editor Richard Lentinello just happens to be a long time member of the Triumph Faithful, so we were very fortunate to have a writer with plenty of TR knowledge handle the scribe duties for this feature. This issue is also extra special to Triumph and British car enthusiasts, because it also has a 12- page feature section titled “British Greats”, and covers a wide range of those LBC’s that we’ve all become so lovingly attached to. Pick up a copy of the August 2020 “Hemmings Classic Car” at your local news stand, or order copies of the July & August issues from Hemmings.com. In the 3 weeks that have passed since I wrote about our TR4 being featured in the July issue, I received the sad news that more great classic auto magazines will cease to be published. First was “American Car Collector”, a companion magazine to Keith Martin’s “Sports Car Market”. This announcement was quickly followed by the news that “Triumph World” from the UK will no longer be printed. Looking back at all of my old sources of automotive reading pleasure, we’ve lost “Hemmings Sports & Exotic Car”, “Old Cars Weekly”, “Autoweek”, and “Street Rodder”, just to name the most recent departures. I’ve also noticed a decrease in the page count of another of my favorites, “Hot Rod”, and I fear that it too may already be headed for the chopping block. I previously recommended that you appreciate the love and dedication that it takes to restore ANY vintage auto or truck, and start a subscription to “Hemmings Classic Car”. Keeping this magazine alive will benefit the entire hobby, in addition to your own reading pleasure. The dark clouds have been gathering on the publishing horizon for some time now, and if we don’t stand up and support them, they may all become extinct before too much longer. I don’t know about you, but I’d hate to have to thumb through the wife’s “Better Homes & Gardens” while hanging out in the throne room!June 15, 2020

It’s a well known fact that the rear differential mounts on the TR4A-TR6 frames are prone to crack (especially the right front mount), so we take a hard look at them any time we have a differential removed for service. There is a strengthening kit available which we always install when a frame is out from under a car (during a complete restoration), but what about cars which aren’t getting the full monty? We used to cut an access hole in the rear floor to install these kits, but we have since learned that if we modify the kit slightly, we can perform the repair 100% from below the car. This photo shows the completed repair, solidly welded in place but before painting, all done with the body left in place and the floor completely undisturbed. We don’t expect that these will ever crack (or break) again!June 8, 2020

We really aren’t in the business of buying and selling TR’s, but we will occasionally pick up a worthy project car, and even cars which can be made into “driver” quality cars that you can enjoy and have fun with. Our ‘Cars 4 Sale’ page has been updated VERY infrequently, and any of you who might be in the market for a driver or a new project have probably stopped checking that page a long time ago. Notice that I didn’t suggest you could find a Macy’s Garage Restoration for sale here (or anywhere else), because that never happens. Of all the TR’s that we have restored, there has only been ONE Macy’s Garage Triumph that ever hit the open market, so the only realistic chance you have to get a TR that was fully restored here is to have it done especially for you. Eventually, the pile of “drivers” and “projects” got so deep that I simply had to update the Cars 4 Sale page. So if you are toying with the idea of acquiring a new “toy”, follow the link above to see what we have available.June 1, 2020

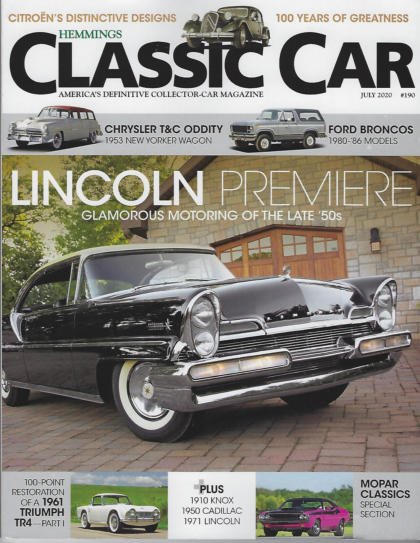

While it’s only a small image in the lower left corner, we did make the cover of Hemmings Classic Car magazine! This July 2020 issue is on the newstands now, that is IF you can find a newstand anymore, and IF they are allowed to be open due to the Corona Virus. You can also order copies directly from Hemmings by calling 1-800-227-4373, or logging onto hemmings.com. But if you have to order, you might wait a couple of weeks until the August 2020 issue is out, because the July issue shown here only contains Part 1 of a 2-part feature on Tonda’s PERFECT 1961 TR4, CT288L. You’ll save a little on the shipping if you order both the July and August issues together. Hemmings Classic Car is an excellent publication, and one that I have subscribed to since Vol. 1, Issue 1. Originally, it covered domestic cars and trucks only, but imports were added when the Hemmings Sports and Exotic Car which I dearly loved went away. If you hold a special place in your heart for vintage vehicles, then you should appreciate the love and effort that goes into preserving and restoring them. It takes the same amount of devotion and skill to restore a Model A Ford that is needed to restore a Triumph, so there’s no need to avoid a publication just because it doesn’t contain enough British cars, or whatever other flavor you might be addicted to! And with so few good automotive publications remaining today, there isn’t a better time to expand your horizons! Pick up a copy to read the 6-page feature on our TR4 in the July issue, and come back for part 2 next month. And after thumbing through the rest of the magazine, you might have to admit to what a great asset this magazine is to the old car hobby, and order a subscription for yourself!May 26, 2020

This week we present a good look at the finished TR3A wheelarch that we created from flat steel. It still needs to have the front apron cross bar bracket installed, and the wire hold down tabs, plus the reinforcement plate for the front overrider support tube, but that’s all minor stuff compared to forming the entire left front corner of the body tub. All of the ancillary small bracket and parts will be added later, after both front fenders and the front apron have been installed, just so we can verify exact locations for precise fit. No matter how many times I see these parts take shape in our shop, I’m still amazed at what talented folks with the best equipment and an intimate knowledge of these cars can do. It’s always a treat to watch a part like this take shape, and another Triumph TR like this one come back from the grave!May 18, 2020

Remember the “Humpty-Dumpty” TR3A that we put together from 2 halves back in March of this year (Blog 2020Q1)? Despite being rusted in two through the middle, the car had also received some accident damage to the left front, and the inner fender (wheelarch/valance) had been wadded up and crudely hammered back out. There was no way that we’d ever be able to make this panel look good when the bonnet was opened to show off the beautifully restored engine bay, so we needed to fabricate a new part to replace the damaged original. This is not the first time we’ve had to create these parts from flat steel, so fortunately we already had a wooden body buck available to help create the needed part. This photo shows step one, the frontal area, and you can see that we’ve not only shaped the compound curves needed to fabricate a perfect part, but we also formed the correct dimples for clearance behind the headlight bucket and the parking/turn signal lamp. While it is true that reproduction parts are listed in the catalogs, our experience has shown us that the time required to make those “repop” parts fit is nearly equal to the time needed to make a part from scratch here in our own metal shop, one that actually fits on the first try, saving the owner the $1000 cost of a part that won’t fit without extensive modification.May 11, 2020

Rich is restoring this TR3A mostly by himself at home, but he couldn’t get the engine to start so he brought the car here for us to work our magic. It was only here for about 2 minutes before we spotted an even bigger problem though. There is a large twist in the body tub, as can be easily seen by looking across the rear cowl to the front cowl. The rear cowl is level, but the front is higher by a full inch on the right. The body tub also measures close to an inch longer on the right side than on the left! This is not accident damage, but rather a floor and sill replacement gone very wrong! The RF fender will never fit, the door will never close, and a top won’t fit with a w/s frame canted like this. It’s unbelievable that no one saw this before now! We asked who had done the paint and bodywork, and Rich was proud that he had Dave, the local “British Car Guru” and a supposed TR3 specialist do all of the paint and bodywork when he lived in NC. While I don’t doubt that The Guru knows a TR3 when he sees one, being able to talk a good story does not make up for a lack of skill or poor workmanship. Now Rich gets to tear the car back apart and drag the body tub back down to NC, where hopefully The Guru will be able to save the car. We could easily fix it here, but we’ll be surprised if Guru Dave can!May 4, 2020

We always schedule TR’s to come here on a first come, first served basis. Through the years, we have often been amused when we just happen to have 3 or 4 cars here in the same color at the same time. Visitors will usually notice and ask if Red, White, or Green was the most prevalent color when the cars were new. We always answer by inviting them to come back in 6 months, by which time the color palette in our shop will have certainly changed. Throughout the many years we’ve watched this changing sea of color, at no time has yellow ever been seen on the majority of TR’s here for service and restoration. To make this recent concentration of yellow even more strange, at no time have we ever had more than 4 cars here at the same time wearing the same color. To now have 6 yellow TR’s show up together from all over North America, and also knowing that our June TR3A restoration start is slated to be another pale yellow car, it makes us want to ask the question, “Is Yellow the new Red?”.April 27, 2020

Those of you who follow this blog might remember seeing this beautiful Dark Navy TR4 featured here on May 20, 2019 after we had just completed a full frame-up restoration. But if you happened to be watching Dennis Gage and “My Classic Car” on TV this past weekend, did you happen to recognize this same TR4 shown prominently in the background as they were discussing a Lotus 7? I certainly did! Parked right next to the Lotus 7, there are several great views of “our” TR4 on the show, and I’ll bet that if the owner Brooks had left the top down (in the rain) like the Lotus 7 owner had (does a 7 even have a top?), the TR4 would have been the featured car instead of the Lotus! I remember hearing about this show from Brooks, and how it had rained all day, but at least he won the British Car class (over the Louts) if I remember correctly. If you’d like to watch this episode, or any of the My Classic Car series, go to myclassiccar.com, and choose season 24, episode 17 from the Highlands, NC Motoring Festival. It’s nice to see any Triumph make it onto the small screen, even if it is only in the background!April 20, 2020

You might not immediately recognize the trouble here, but you’d probably figure it out eventually, like when it was time to install the fan belt. Someone who previously had their hands on this TR3 crankshaft hub and fan extension, installed the pulley backwards, which moved it back under the timing pointer. (They also had it “indexed” incorrectly, but that’s a subject for another time.) Now the belt doesn’t actually need to go between the pointer and the pulley, but the crankshaft pulley does need to align with generator and water pump pulleys. The tip of the timing pointer also needs to point to the hole in the rear pulley half, which it still does because the rear half has been installed on the front, and the front half is on the back, causing it to scrape slightly on the timing cover! Fortunately, we spotted this mistake immediately, and before the engine was installed into the car (and more importantly, before the radiator and front apron were back on the car). Any shop less fluent in TR’s would have certainly been facing several hours of re-work to tear it all apart again for access, and undoubtedly the owner would have been paying for their lack of Triumph knowledge.April 13, 2020

We rebuild a huge number of SU and Z-S carburetors here each year, but this is the first time we’ve run into this particular problem. In most cases, we will supply the carburetor “kit” from our own inventory, but this time the client had already purchased a kit and we reluctantly agreed to install it, even though it wasn’t our usual brand. The kit was packaged as two individual kits, one for each carburetor, and after checking that they had the same part number on each package, we proceeded to rebuild the carbs one at a time without thinking that anything might be amiss. Only after the rebuild process was complete, and tuning commenced with the carbs back on the engine, did we realize that there was a huge problem. One carburetor did start to dial-in, but we could not do anything to make the second one rich enough to match the first. The carbs were removed and partially torn-down until the problem was revealed. The jets in the client supplied kit didn’t match, and any perceived cost savings the owner thought he would have by sourcing his own parts quickly vanished in the additional labor needed to sort out the mis-matched parts he supplied. We do this enough that we know where to buy what parts, and we always order quality over low cost!April 6, 2020

Here’s a little amusement to share with you during these troubled times, the inside of a TR3A front fender that was “repaired” at sometime in the distant past. Look closely along the bottom edge of the fender, in what is known to be a typical rust spot on these cars. Yes, that is a block of wood you see here, installed to hold the bondo “fix” in a big rust hole. Now we’ve seen plenty of metal patches that were brazed, screwed, or pop riveted over a hole to back-up the bondo, and we’ve found more than our share of cardboard and wadded up newspaper on multiple occasions. We’ve even seen duct tape, screen wire, and fiberglass used for this purpose, but I think this is the first time that we’ve found a block of wood used to back-up the bondo until it hardened. I’ve heard rust holes described as caused by “metal termites” many times over the years, so perhaps using wood as part of the “repair” is inviting REAL trouble?

BLOG

2020-Q2

America’s BEST Triumph Shop

Macy’s Garage

© 2026 - Macy’s Garage, Ltd.

Blog

WHAT we’re doing, and HOW we’re doing it!

June 29, 2020

Preparing to paint the signature stripe on a TR250 is a lengthy and tedious process. Moss has a nice instruction sheet available, but because none of the lines are parallel to a straight body line, and crossing surfaces that are anything but flat, it takes great care and patience to get the stripe layed out correctly. We don’t want to chance that the stripe won’t align from panel to panel, so we always assemble the fenders and hood, and then begin the taping process. Don’t forget to install the fender beading as well, because the stripe goes right across the painted beads. We can assume that Triumph did not take this kind of time when laying out these stripes, and it would have been interesting to see what kind of stencil or mask they used to fit one to such a convoluted surface. We know the stripe was applied with the front ends completely assembled because we’ve seen original cars with overspray in the cracks between fenders and hood, but we always take them back apart to paint after the layout is complete. That way we can tape off the back sides and control the overspray, making a much neater job than could have been accomplished in a production factory. June 22, 2020 The August 2020 issue of “Hemmings Classic Car” is here, and once again there’s a Triumph TR4 on the cover! Part two of the 2-issue feature on Tonda’s earlyTR4, CT288L is included on pages 80-85, and covers the final assembly and some of the details which distinguish this and other early production TR4’s from the later cars that followed. Executive Editor Richard Lentinello just happens to be a long time member of the Triumph Faithful, so we were very fortunate to have a writer with plenty of TR knowledge handle the scribe duties for this feature. This issue is also extra special to Triumph and British car enthusiasts, because it also has a 12-page feature section titled “British Greats”, and covers a wide range of those LBC’s that we’ve all become so lovingly attached to. Pick up a copy of the August 2020 “Hemmings Classic Car” at your local news stand, or order copies of the July & August issues from Hemmings.com.June 15, 2020

It’s a well known fact that the rear differential mounts on the TR4A-TR6 frames are prone to crack (especially the right front mount), so we take a hard look at them any time we have a differential removed for service. There is a strengthening kit available which we always install when a frame is out from under a car (during a complete restoration), but what about cars which aren’t getting the full monty? We used to cut an access hole in the rear floor to install these kits, but we have since learned that if we modify the kit slightly, we can perform the repair 100% from below the car. This photo shows the completed repair, solidly welded in place but before painting, all done with the body left in place and the floor completely undisturbed. We don’t expect that these will ever crack (or break) again!June 8, 2020

We really aren’t in the business of buying and selling TR’s, but we will occasionally pick up a worthy project car, and even cars which can be made into “driver” quality cars that you can enjoy and have fun with. Our ‘Cars 4 Sale’ page has been updated VERY infrequently, and any of you who might be in the market for a driver or a new project have probably stopped checking that page a long time ago. Notice that I didn’t suggest you could find a Macy’s Garage Restoration for sale here (or anywhere else), because that never happens. Of all the TR’s that we have restored, there has only been ONE Macy’s Garage Triumph that ever hit the open market, so the only realistic chance you have to get a TR that was fully restored here is to have it done especially for you. Eventually, the pile of “drivers” and “projects” got so deep that I simply had to update the Cars 4 Sale page. So if you are toying with the idea of acquiring a new “toy”, follow the Site Navigation button to see what’s available.June 1, 2020

While it’s only a small image in the lower left corner, we did make the cover of Hemmings Classic Car magazine! This July 2020 issue is on the newstands now, that is IF you can find a newstand anymore, and IF they are allowed to be open due to the Corona Virus. You can also order copies directly from Hemmings by calling 1-800-227-4373, or logging onto hemmings.com. But if you have to order, you might wait a couple of weeks until the August 2020 issue is out, because the July issue shown here only contains Part 1 of a 2-part feature on Tonda’s PERFECT 1961 TR4, CT288L. You’ll save a little on the shipping if you order both the July and August issues together. Hemmings Classic Car is an excellent publication, and one that I have subscribed to since Vol. 1, Issue 1. Originally, it covered domestic cars and trucks only, but imports were added when the Hemmings Sports and Exotic Car which I dearly loved went away. If you hold a special place in your heart for vintage vehicles, then you should appreciate the love and effort that goes into preserving and restoring them. It takes the same amount of devotion and skill to restore a Model A Ford that is needed to restore a Triumph, so there’s no need to avoid a publication just because it doesn’t contain enough British cars, or whatever other flavor you might be addicted to! And with so few good automotive publications remaining today, there isn’t a better time to expand your horizons! Pick up a copy to read the 6- page feature on our TR4 in the July issue, and come back for part 2 next month. And after thumbing through the rest of the magazine, you might have to admit to what a great asset this magazine is to the old car hobby, and order a subscription for yourself!May 26, 2020

This week we present a good look at the finished TR3A wheelarch that we created from flat steel. It still needs to have the front apron cross bar bracket installed, and the wire hold down tabs, plus the reinforcement plate for the front overrider support tube, but that’s all minor stuff compared to forming the entire left front corner of the body tub. All of the ancillary small bracket and parts will be added later, after both front fenders and the front apron have been installed, just so we can verify exact locations for precise fit. No matter how many times I see these parts take shape in our shop, I’m still amazed at what talented folks with the best equipment and an intimate knowledge of these cars can do. It’s always a treat to watch a part like this take shape, and another Triumph TR like this one come back from the grave!May 18, 2020

Remember the “Humpty-Dumpty” TR3A that we put together from 2 halves back in March of this year (Blog 2020Q1)? Despite being rusted in two through the middle, the car had also received some accident damage to the left front, and the inner fender (wheelarch/valance) had been wadded up and crudely hammered back out. There was no way that we’d ever be able to make this panel look good when the bonnet was opened to show off the beautifully restored engine bay, so we needed to fabricate a new part to replace the damaged original. This is not the first time we’ve had to create these parts from flat steel, so fortunately we already had a wooden body buck available to help create the needed part. This photo shows step one, the frontal area, and you can see that we’ve not only shaped the compound curves needed to fabricate a perfect part, but we also formed the correct dimples for clearance behind the headlight bucket and the parking/turn signal lamp. While it is true that reproduction parts are listed in the catalogs, our experience has shown us that the time required to make those “repop” parts fit is nearly equal to the time needed to make a part from scratch here in our own metal shop, one that actually fits on the first try, saving the owner the $1000 cost of a part that won’t fit without extensive modification.May 11, 2020

Rich is restoring this TR3A mostly by himself at home, but he couldn’t get the engine to start so he brought the car here for us to work our magic. It was only here for about 2 minutes before we spotted an even bigger problem though. There is a large twist in the body tub, as can be easily seen by looking across the rear cowl to the front cowl. The rear cowl is level, but the front is higher by a full inch on the right. The body tub also measures close to an inch longer on the right side than on the left! This is not accident damage, but rather a floor and sill replacement gone very wrong! The RF fender will never fit, the door will never close, and a top won’t fit with a w/s frame canted like this. It’s unbelievable that no one saw this before now! We asked who had done the paint and bodywork, and Rich was proud that he had Dave, the local “British Car Guru” and a supposed TR3 specialist do all of the paint and bodywork when he lived in NC. While I don’t doubt that The Guru knows a TR3 when he sees one, being able to talk a good story does not make up for a lack of skill or poor workmanship. Now Rich gets to tear the car back apart and drag the body tub back down to NC, where hopefully The Guru will be able to save the car. We could easily fix it here, but we’ll be surprised if Guru Dave can!May 4, 2020

We always schedule TR’s to come here on a first come, first served basis. Through the years, we have often been amused when we just happen to have 3 or 4 cars here in the same color at the same time. Visitors will usually notice and ask if Red, White, or Green was the most prevalent color when the cars were new. We always answer by inviting them to come back in 6 months, by which time the color palette in our shop will have certainly changed. Throughout the many years we’ve watched this changing sea of color, at no time has yellow ever been seen on the majority of TR’s here for service and restoration. To make this recent concentration of yellow even more strange, at no time have we ever had more than 4 cars here at the same time wearing the same color. To now have 6 yellow TR’s show up together from all over North America, and also knowing that our June TR3A restoration start is slated to be another pale yellow car, it makes us want to ask the question, “Is Yellow the new Red?”.April 27, 2020

Those of you who follow this blog might remember seeing this beautiful Dark Navy TR4 featured here on May 20, 2019 after we had just completed a full frame-up restoration. But if you happened to be watching Dennis Gage and “My Classic Car” on TV this past weekend, did you happen to recognize this same TR4 shown prominently in the background while they were discussing a Lotus 7? I certainly did! Parked right next to the Lotus 7, there are several great views of “our” TR4 on the show, and I’ll bet that if the owner Brooks had left the top down (in the rain) like the Lotus 7 owner had (does a 7 even have a top?), the TR4 would have been the featured car instead of the Lotus! I remember hearing about this show from Brooks, and how it had rained all day, but at least he won the British Car class (over the Lotus) if I remember correctly. If you’d like to watch this episode, or any of the My Classic Car series, go to myclassiccar.com, and choose season 24, episode 17 from the Highlands, NC Motoring Festival. It’s nice to see any Triumph make it onto the small screen, even if it is only in the background!April 20, 2020

You might not immediately recognize the trouble here, but you’d probably figure it out eventually, like when it was time to install the fan belt. Someone who previously had their hands on this TR3 crankshaft hub and fan extension, installed the pulley backwards, which moved it back under the timing pointer. (They also had it “indexed” incorrectly, but that’s a subject for another time.) Now the belt doesn’t actually need to go between the pointer and the pulley, but the crankshaft pulley does need to align with generator and water pump pulleys. The tip of the timing pointer also needs to point to the hole in the rear pulley half, which it still does because the rear half has been installed on the front, and the front half is on the back, causing it to scrape slightly on the timing cover! Fortunately, we spotted this mistake immediately, and before the engine was installed into the car (and more importantly, before the radiator and front apron were back on the car). Any shop less fluent in TR’s would have certainly been facing several hours of re- work to tear it all apart again for access, and undoubtedly the owner would have been paying for their lack of Triumph knowledge.April 13, 2020

We rebuild a huge number of SU and Z-S carburetors here each year, but this is the first time we’ve run into this particular problem. In most cases, we will supply the carburetor “kit” from our own inventory, but this time the client had already purchased a kit and we reluctantly agreed to install it, even though it wasn’t our usual brand. The kit was packaged as two individual kits, one for each carburetor, and after checking that they had the same part number on each package, we proceeded to rebuild the carbs one at a time without thinking that anything might be amiss. Only after the rebuild process was complete, and tuning commenced with the carbs back on the engine, did we realize that there was a huge problem. One carburetor did start to dial-in, but we could not do anything to make the second one rich enough to match the first. The carbs were removed and partially torn-down until the problem was revealed. The jets in the client supplied kit didn’t match, and any perceived cost savings the owner thought he would have by sourcing his own parts quickly vanished in the additional labor needed to sort out the mis-matched parts he supplied. We do this enough that we know where to buy what parts, and we always order quality over low cost!April 6, 2020

Here’s a little amusement to share with you during these troubled times, the inside of a TR3A front fender that was “repaired” at sometime in the distant past. Look closely along the bottom edge of the fender, in what is known to be a typical rust spot on these cars. Yes, that is a block of wood you see here, installed to hold the bondo “fix” in a big rust hole. Now we’ve seen plenty of metal patches that were brazed, screwed, or pop riveted over a hole to back- up the bondo, and we’ve found more than our share of cardboard and wadded up newspaper on multiple occasions. We’ve even seen duct tape, screen wire, and fiberglass used for this purpose, but I think this is the first time that we’ve found a block of wood used to back-up the bondo until it hardened. I’ve heard rust holes described as caused by “metal termites” many times over the years, so perhaps using wood as part of the “repair” is inviting REAL trouble?

America’s BEST Triumph Shop